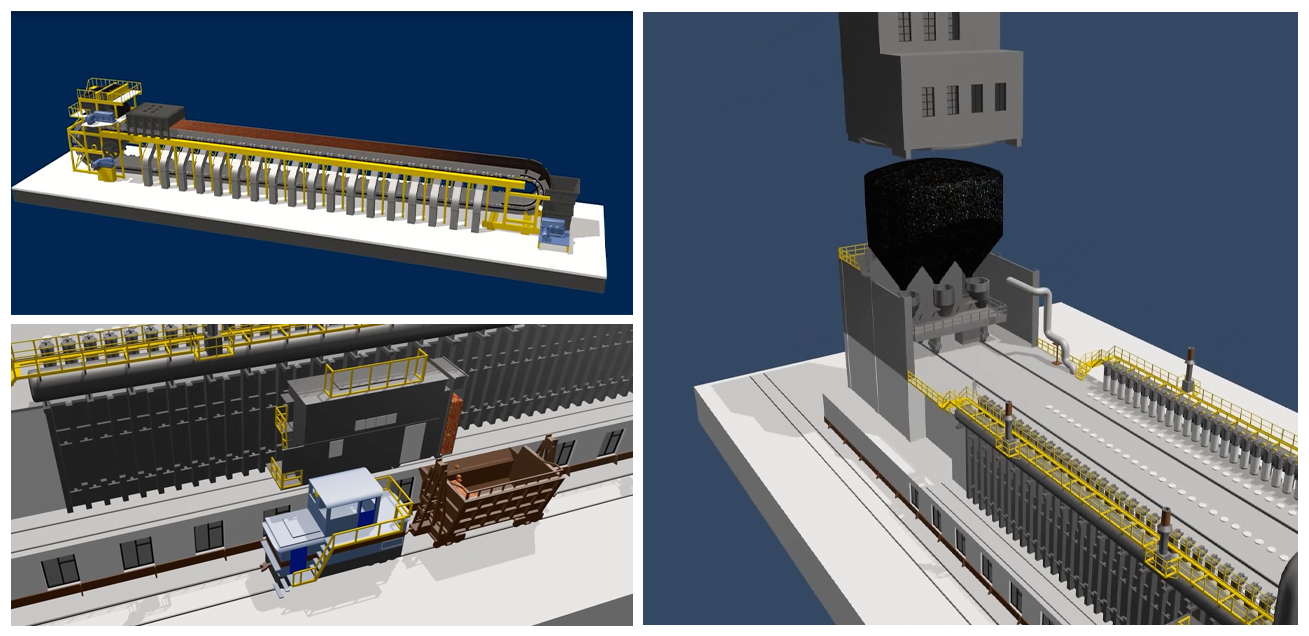

3D models and animation of coke oven battery and sintering machine

For the Ariseum developed AR mobile app demonstrating the function of metallurgical production, our specialists have produced 3D models and animations of the sintering machine and coke oven battery.

Customer's background

Metallurgical Works is an enterprise with a full metallurgical cycle, which includes more than 100 large technological units involving processing iron ore materials and coal to rerolling equipment.

Task

Develop 3D models of the sintering machine and coke oven battery for demonstration through mobile app at the Severstal Museum.

What we have provided

- We got acquainted in detail with the sintering and coke production process

- Studied materials sent by the customer and manufacturer's representatives.

- Based on the obtained data, we shaped the geometry of 3D models of the sintering machine and coke oven battery, including internal parts, which should be animated.

- Developed original textures

- Optimized models for proper function on mobile devices

Solution

After deep analysis of materials and illustrating sinter and coke production, professional modellers of Ariseum Company started to model geometric structures of the sintering machine and coke battery models.

Our specialists have recreated some important parts of the coke oven battery:

- Coal tower, consisting of 3 parts

- Coke battery

- Loading wagon

- Bunkers with a charge

- Coke pusher

- Coke guides basket

- Door removing machine

- Electric locomotive with a coke wagon

- Plannar bar

- Chimney

- Coking chamber in section

As well as part models of a sintering machine:

- Gas collector

- Vacuum chambers

- Loading bunker

- Drum feeder

- Sintering carriage

- Incendiary horn

- Crusher

Based on the developed models, animators launched the production process according to the following scenario for the by-product coke production:

- Loading the charge into the coke oven

- Laying the charge in the furnace and leveling the surface

- The oven sealing

- The charge heating

- The Removal of gases from the furnace

- The change in temperature and time of coking

- Removing/closing the door from the machine side

- Starting/closing the door-removing machine from the coke side

And for sinter production:

- Loading the charge and its circulation in the bunker

- The drum rotation and material movement into the sintering carriage

- Moving the cart towards the incendiary horn

- Unloading and crushing of sinter

In addition, special effects were produced showing the processes that occurs during production: Smoke, water, sparks, fire, dust, change of color of sinter during heating and cooling, transparency of the carriage walls to show the processes inside, and others.

3 modelers and 2 animators worked on the project.